Stainless Steel Corrugated Sheets: The Versatile Choice for Metal Fabrication

Metal fabrication encompasses a vast array of processes, techniques, and materials that enable the creation of various products and structures. Among these materials, stainless steel corrugated sheets have become increasingly popular in both commercial and residential applications due to their strength, durability, and aesthetic appeal. Let's delve deeper into the world of stainless steel corrugated sheets, their applications, and the advantages that make them a preferred choice in the industry.

Understanding Stainless Steel Corrugated Sheets

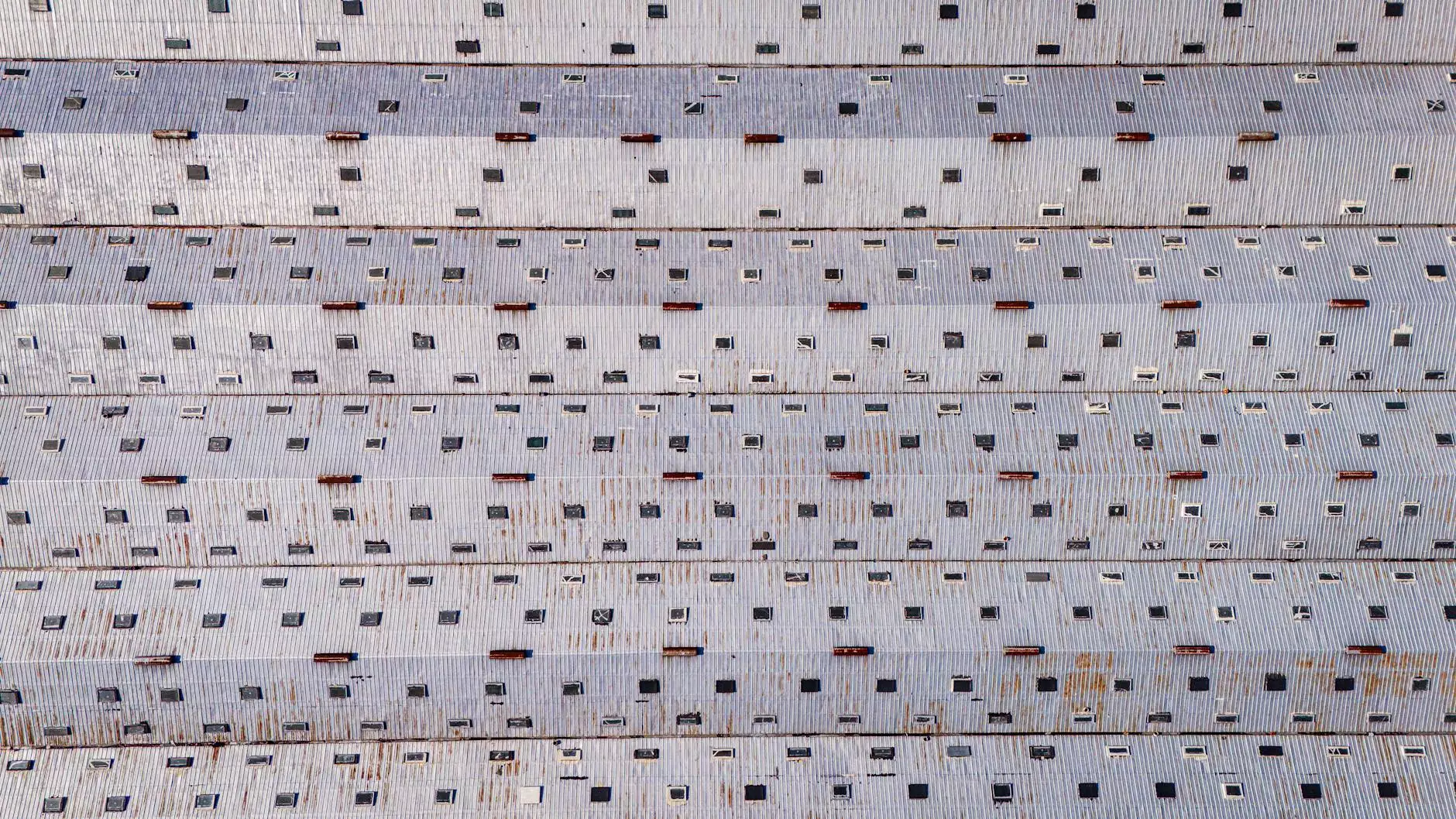

Stainless steel corrugated sheets are formed by processing stainless steel into a wavy pattern, resulting in a product that combines unique visual appeal with enhanced structural integrity. This specific type of sheet metal is available in various grades, dimensions, and finishes, making it highly versatile for different applications.

Composition and Properties

The primary component of stainless steel is iron, but the addition of at least 10.5% chromium gives it unique properties that contribute to its performance:

- Corrosion Resistance: The chromium content forms a protective layer on the metal surface, preventing oxidation and rust.

- Durability: Stainless steel is known for its strength, making it a reliable choice for various structural applications.

- Temperature Resistance: It can withstand high temperatures, retaining structural integrity even under extreme conditions.

- Aesthetic Versatility: Available in various finishes that enhance its visual appeal, making it suitable for architectural designs.

Applications of Stainless Steel Corrugated Sheets

The applications of stainless steel corrugated sheets are vast, ranging from industrial to domestic contexts. Here are some of the key areas where these materials are utilized:

1. Construction Industry

In construction, stainless steel corrugated sheets are employed for:

- Roofing: Their lightweight yet sturdy nature makes them perfect for roofing solutions that require strong materials to withstand weather conditions.

- Wall Cladding: The sheets are used for both exterior and interior wall cladding, providing visual appeal and added protection against the elements.

- Canopies and Awnings: The versatility of the material allows for creative designs in canopies and awnings, enhancing aesthetic appeal while offering protection.

2. Agricultural Sector

In agriculture, these sheets offer several advantages, such as:

- Livestock Shelters: They are used to construct durable and weather-resistant animal shelters and barns.

- Storage Sheds: Farmers utilize stainless steel corrugated sheets for building storage facilities that resist corrosion from fertilizers, chemicals, and moisture.

3. Architectural Applications

Architects and designers have found innovative ways to integrate stainless steel corrugated sheets into their projects:

- Modern Facades: They are chosen for modern building facades, thanks to their contemporary look and ability to reflect light.

- Sculptural Elements: The flexibility of stainless steel allows artists to create sculptural installations and decorative features that enhance urban landscapes.

Benefits of Using Stainless Steel Corrugated Sheets

The choice to use stainless steel corrugated sheets is informed by various advantages that these sheets offer:

1. Longevity

Stainless steel is known for its remarkable lifespan, often exceeding 50 years with minimal maintenance. Its natural resistance to corrosion reduces the need for frequent replacements, making it a cost-effective solution in the long run.

2. Low Maintenance

Unlike other materials that may require regular painting or treatment, stainless steel corrugated sheets can be easily cleaned with water and mild detergents, preserving their appearance with minimal effort.

3. Eco-Friendly Choice

Stainless steel is 100% recyclable, making it an environmentally friendly choice. By opting for stainless steel products, you contribute to sustainability efforts by reducing waste and promoting recycling.

4. Safety and Hygiene

In industries such as food processing and pharmaceuticals, hygiene is paramount. Stainless steel’s non-porous surface inhibits the growth of bacteria, making it a safe option for applications that require high sanitary standards.

Choosing the Right Stainless Steel Corrugated Sheet

Selecting the appropriate stainless steel corrugated sheet requires careful consideration of several factors:

1. Grade Selection

There are various grades of stainless steel, each offering different properties. The two most common grades used in corrugated sheets are:

- 304 Stainless Steel: A general-purpose grade with excellent corrosion resistance, suitable for various applications.

- 316 Stainless Steel: Contains molybdenum, providing even better resistance to corrosion, especially in marine environments.

2. Thickness and Profile

Consider the thickness and profile of the sheets you require for your project. Thicker sheets offer enhanced durability but may be heavier and more expensive. Evaluate the needs of your specific application to select the right specifications.

3. Finish and Aesthetic Considerations

Stainless steel can be finished in various ways (e.g., polished, brushed, or matte). Choose a finish that complements the design and aesthetic needs of your project.

Installation Tips for Stainless Steel Corrugated Sheets

Proper installation is crucial to ensure the performance and longevity of stainless steel corrugated sheets:

1. Prepare Your Structure

Ensure that the underlying structure is structurally sound and appropriately aligned. Any irregularities can lead to issues during installation.

2. Use Appropriate Fasteners

Choose fasteners made from stainless steel to prevent galvanic corrosion due to dissimilar metals. Ensure fasteners are installed securely, following manufacturer recommendations.

3. Allow for Expansion

Stainless steel expands and contracts with temperature changes. Allow for adequate space between sheets and at the edges to accommodate this thermal movement.

Conclusion: The Superior Choice for Metal Fabricators

In summary, stainless steel corrugated sheets present an array of advantages, from their impressive longevity and low maintenance needs to their aesthetic versatility and strength. As a metal fabricator, choosing stainless steel corrugated sheets can enhance the quality and durability of your projects. With its wide range of applications, sustainability, and ability to meet high hygiene standards, it stands as a superior choice in the industry.

For all your metal fabrication needs, consider relying on expert providers like Goldecosteel. We offer high-quality stainless steel products tailored to your specific requirements, ensuring exceptional results for every project.

Explore the potential of stainless steel corrugated sheets and elevate your projects to new heights! Whether you are in construction, agriculture, or architecture, this versatile material is sure to meet your needs with reliability and style.